|

Due to the dramatic beginning of the Great Patriotic War, the Red Army lost almost all of its armored fighting vehicles and a large part of its artillery. At the time, the loss or evacuation of most of the Soviet factories meant that Soviet industry was unable to compensate for heavy Red Army losses. At that crucial moment every weapon that was available was used. There were many captured weapons from the First World War and the Russian-Japanese War stored in Red Army warehouses and arsenals, and they were now sent to the front. There were cases of ex-Japanese 105-mm guns, Arisaka rifles, and ex-German howitzers being used. The Germans captured many Soviet vehicles. However, in spite of the Red Army being on the defensive, some German vehicles had also been captured. According to the report of the  NKV, about 20-40% of all captured vehicles couldn't be repaired because of a lack of spare parts, and especially a lack of armament parts. To solve the problem, on December 21, 1941 NKV ordered all Soviet factories to make proposals for re-arming captured tanks with domestic armament. Some of the factories had time to built prototypes. These vehicles were shown to the NKV commission in February and March of 1942. Among those vehicles there was one from Factory #592. Work on the self-propelled gun was started before evacuation in the design bureau of Factory #592, although the factory's engineers weren't experienced in developing combat vehicles. In September 1941, the factory was redirected to repair tanks and artillery equipment, including captured vehicles (as time progressed, the number of them had grown extensively). NKV, about 20-40% of all captured vehicles couldn't be repaired because of a lack of spare parts, and especially a lack of armament parts. To solve the problem, on December 21, 1941 NKV ordered all Soviet factories to make proposals for re-arming captured tanks with domestic armament. Some of the factories had time to built prototypes. These vehicles were shown to the NKV commission in February and March of 1942. Among those vehicles there was one from Factory #592. Work on the self-propelled gun was started before evacuation in the design bureau of Factory #592, although the factory's engineers weren't experienced in developing combat vehicles. In September 1941, the factory was redirected to repair tanks and artillery equipment, including captured vehicles (as time progressed, the number of them had grown extensively). I have been unable to find the exact date of starting work on the 122 mm self-propelled gun, but surviving blueprints are dated April 1942. The follow letter confirms this date: «Top Secret.

To the Chief of the Repairing Center of the ABTU KA brigade-engineer Sosenkov.

Copy: to the Director of the Factory #592 Pankratov. According to the decision of the Deputy of the Minister of Defense of the USSR Lieutenant-General comrade Fedoreno, captured Artsturms must be re-armed with the domestic 122 mm Howitzer M-30 Model 1938 in Factory #592. I ask you to give an order to repair and deliver four captured „artsturms‛ to Factory #592. To accelerate the process, the first repaired Artsturm must be delivered to the factory before April 25. April 13, 1942.

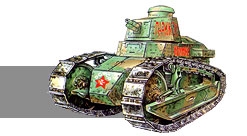

The Chairman of the Tech Council, E. Satel» The project designed by the group of engineers lead by A. Kashtanov was very simple. The new vehicle was based on the captured German StuG III with a new, more spacious, fighting compartment that allowed the mounting of the 122 mm Howitzer M-30 (the same as on the Soviet SU-122). Why exactly the 122 mm howitzer? This was no accidental choice: at that time there was great shortage of 76-mm guns, while heavy 122 mm howitzers accumulated in the rear due to lack of limbers and artillery tractors. Therefore, the new 122 mm self-propelled gun was evaluated very high. In May 1942, the vehicle was sent to trials. By that time, it was named «The Self-Propelled Assault Gun SG-122 (Artsturm)» or simply the SG-122(A) (the SG means Samokhodnaya Gaubitza — Self-Propelled Howitzer). According to the existing description of the first prototype of the SG-122(A), it was based on either the StuG III Ausf C or the StuG III Ausf D. The original fighting compartment was removed and then a simple squared box was fitted. It was assembled (welded) of 45mm armored plate on the front and of 25–35 mm plates on the rear and sides. The horizontal welding seam was strengthened with 6–8 mm steel straps to provide it with additional strength. Inside the fighting compartment was the M-30 howitzer instead of the original StuK 37. Most of the ammunition was distributed along the sides of the compartment, but some of the shells were stored on the bottom behind the howitzer's mounting. The crew of the SG-122(A) was five men: the driver (located forward-left the vehicle); the commander (behind the driver); the first loader (behind the commander, who also operated the radio); the gunner (to the right of the commander); and the second loader (behind the gunner). The vehicle had two hatches: the first one located in the rear of the fighting compartment; the second one located in the front of the compartment (in front of the gunner). The SG-122(A) retained the original German radio. Unfortunately, I have no data about the internal communication devices. The vehicle was tested by being run on gravel roads and run cross-country a total distance of 480 km. The vehicle fired 66 shots, both direct and indirect. All the trials confirmed good combat capabilities, but some disadvantages had been noticed, most important were: 1. Insufficient rough-terrain performance and overloading of the front roadwheels; 2. Too many duties for the commander, who must spot, aim the gun, command the crew etc; 3. Insufficient fuel capacity; 4. Impossibility to fire personal weapons from the pistol ports because of their poor layout; 5. Insufficient strength of the fighting compartment; 6. Insufficient ventilation of the fighting compartment. The factory was ordered to improve all these shortcomings by developing an improved vehicle. It was also recommended to develop a new fighting compartment to fit on captured Pz-III tanks, which were much more numerous than captured StuG's, and it was recommended to make side hatch (es) for better evacuation from the vehicle. After analyzing all the shortcomings and fixing them, Factory #592 manufactured two improved SG-122(A). The type of chassis used distinguished them: the first one used the StuG's chassis while the second one was based on the chassis of the PzKpfw III. Both these vehicles were distinguished from the first prototype by the following improvements: 1. The fighting compartment was made of thinner armor (35 mm front; 25 mm sides and rear). This decreased the whole weight of the vehicle and therefore increased its rough-terrain performance; 2. The crew duties were altered. Now, the gunner was placed in front of the commander and received his own hatch in the roof of the compartment (the hatch in the front of the compartment was removed). The commander received an artillery reconnaissance sight (like a submarine periscope), and he had a panoramic sight mounted in the hatch; 3. The German side pistol ports were replaced with Soviet-type (OGK  NKTP) ports, which were developed for the «76-mm support assault gun.» New ports allowed the firing of the Nagant and TT pistols and the PPSh submachine-gun; NKTP) ports, which were developed for the «76-mm support assault gun.» New ports allowed the firing of the Nagant and TT pistols and the PPSh submachine-gun; 4. The whole weight of the gun mount was decreased. To simplify the load, the gun was equipped with a folding tray. The new electrical ventilator was mounted over the breech-block of the gun; 5. To increase the fuel capacity, the SG-122(A) received external squared fuel tanks (from the BT and T-34 tanks), which were fitted on the sides. The original German entrenching tools were replaced with Soviet tools; 6. The radio was relocated from the left side to the right in the fighting compartment. To increase the protection, it was recommended to angle the side armor of the fighting compartment 10-20°. Especially for the SG-122(A), the  Uralmash Factory developed a cast gun mantlet. This mantlet was much better and cheaper than the original one — it did a better job of protecting the gun from bullets and shell fragments, and it allowed the removal of the large shields which were installed on both sides of the gun (these shields were quite heavy and thus overloaded the front roadwheels). Uralmash Factory developed a cast gun mantlet. This mantlet was much better and cheaper than the original one — it did a better job of protecting the gun from bullets and shell fragments, and it allowed the removal of the large shields which were installed on both sides of the gun (these shields were quite heavy and thus overloaded the front roadwheels). In September 1942, Factory #592 was ordered to produce ten improved SG-122(A). Most probably, the order wasn't accomplished due to a lack of armor plates and captured German vehicles. It is interesting to note that employees of the factory insisted that they were delivering SG-122's from May 1942. They also mentioned that they couldn't start frost-bound German engines, and Soviet drivers poured burning petrol in the carburetor to start the engine. Nevertheless I think it wasn't 1942, but 1943, when the the SU-76i appeared. Today I have no exact data about the total number of SG-122's manufactured. Until the end of 1942, eight self-propelled guns (both 122-mm and 76-mm) were made using the StuG's chassis, also two vehicles were built using the Pz-III and Pz-IV chassis. By November 15, 1942, there were three experimental SG-122(A) on the Sverdlovsk proving ground, two of them using the StuG's chassis. On December 5, 1942, one of the SG-122(A) based on the Pz-III was delivered to the Gorokhovetsij proving ground for the comparative trials with the U-35 (further SU-122). After comparative trials, the production plan for 1943 was cancelled. On February 11, 1943, all existing SG-122s (including experimental vehicles) were placed at the disposal of the Chief of the GBTU to form training self-propelled regiments. Proof-reader: Mark Jaremco

Sources: I. Moshanskij, M. Kolomietz «Trophei v Krasnoj Armii» Frontovaya Illustratzia #1, 2000;

«Polygon» #1, 2000

|

NKV

NKV